Trong lĩnh vực chữa cháy, máy bơm lửa, là một thành phần cốt lõi của xe cứu hỏa, ảnh hưởng trực tiếp đến hiệu quả và hiệu quả của việc dập lửa Trong số đó, máy bơm chữa cháy xe áp suất thấp CB10/100 đã đạt được sự công nhận và ứng dụng rộng rãi do hiệu suất và độ tin cậy tuyệt vời của nó

I Giới thiệu về máy bơm lửa CB10/100

Máy bơm chữa cháy xe áp suất thấp CB10/100-XZ áp dụng cấu trúc ly tâm vane hai giai đoạn, thể hiện hiệu suất của máy bơm nổi bật Bánh công tác của nó có thể được làm bằng thép không gỉ hoặc đồng thau, đảm bảo độ bền và độ ổn định của cơ thể bơm

Ngoài ra, máy bơm lửa này có tốc độ quay thấp, hoạt động ổn định và chất lượng đáng tin cậy Hệ thống mồi sử dụng một thiết bị bốn piston điện, cùng với van kiểm tra, để đảm bảo hoạt động đáng tin cậy của bơm lửa trong môi trường phức tạp

Bảng sau đây trình bày các tham số hiệu suất hoạt động của bơm lửa CB10/100-XZ theo các mô hình khác nhau, bao gồm tốc độ dòng chảy, áp suất đầu ra, tốc độ định mức, công suất trục và độ sâu hút Những dữ liệu này cung cấp các tài liệu tham khảo quan trọng để người dùng chọn và định cấu hình máy bơm lửa theo các nhu cầu khác nhau

| Người mẫu | Điều kiện làm việc | Tốc độ dòng chảy | Áp lực đầu ra | Tốc độ định mức | Quyền lực | Độ sâu hút |

| (L/s) | (MPA) | (r/phút) | (Kw) | (m) | ||

| CB10/100-XZ | 1 | 100 | 1 | 2270±50 | 149 | 3 |

| 2 | 70 | 1. 3 | 2320±50 | 138 | 3 | |

| 3 | 50 | 1 | 2050±50 | 115 | 7 |

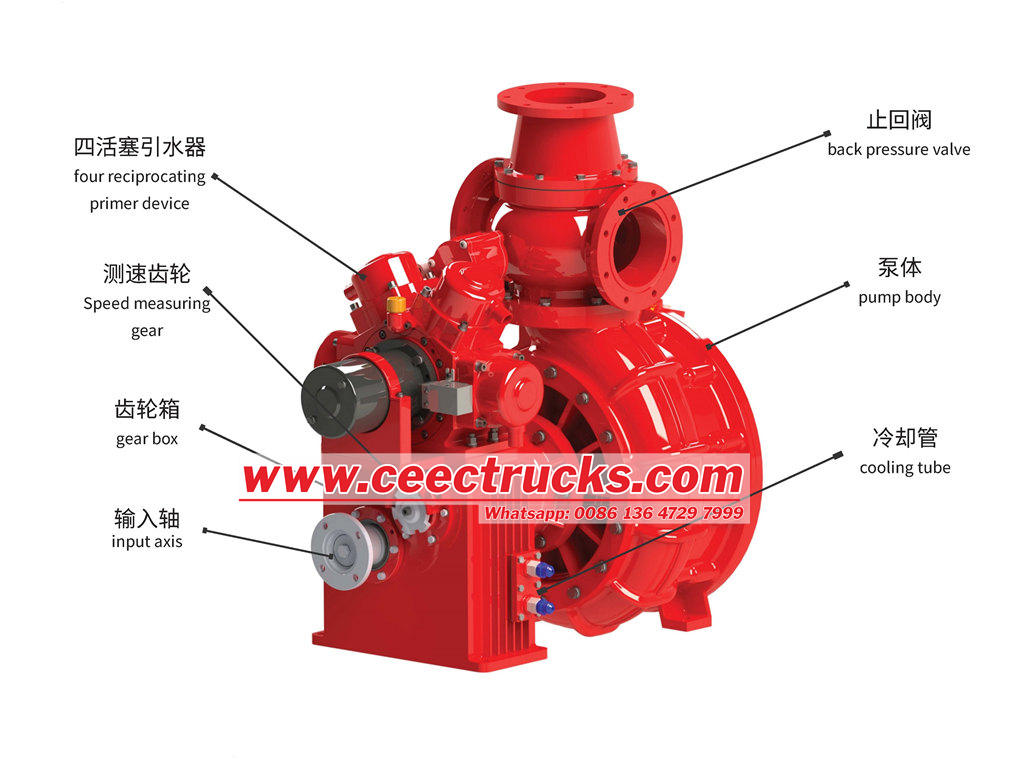

Ii Cấu trúc của máy bơm lửa CB10/100

Máy bơm lửa CB10/100 chủ yếu bao gồm các thành phần sau:

1 Bốn pít-tông: Nó đưa chất lỏng vào máy bơm thông qua chuyển động đối ứng của bốn pít-tông, đóng vai trò là thành phần chính trong quá trình mồi của bơm lửa

2 Kiểm tra van: Nó đảm bảo lưu lượng chất lỏng một chiều, ngăn chặn dòng chảy và đảm bảo hoạt động bình thường của máy bơm

3 Thiết bị đo tốc độ: Nó theo dõi tốc độ quay của máy bơm trong thời gian thực, cung cấp hỗ trợ dữ liệu chính xác cho các nhà khai thác để đảm bảo máy bơm hoạt động trong phạm vi làm việc hiệu quả

4 Cơ thể bơm: Đây là phần chính của cấu trúc ly tâm dây thy hai giai đoạn nơi bánh công tác quay để tạo ra lực ly tâm, cung cấp chất lỏng ở áp suất cao

5 Hộp số: Nó truyền năng lượng đến trục đầu vào, điều khiển bánh công tác quay và duy trì nhiệt độ ổn định thông qua việc lưu thông nước làm mát trong các ống làm mát

6 Đường ống làm mát: Họ đảm bảo rằng hộp số và vòng bi không quá nóng trong quá trình hoạt động, tăng cường tuổi thọ dịch vụ của máy bơm

7 Trục đầu vào: Nó kết nối động cơ và hộp số, truyền năng lượng đến thân máy bơm để điều khiển vòng quay của bánh công tác

Các thành phần này được thiết kế tỉ mỉ và được sản xuất chính xác, đảm bảo hiệu suất và độ bền chung của máy bơm lửa CB10/100

Iii Nguyên tắc làm việc của máy bơm lửa CB10/100

Nguyên tắc làm việc của máy bơm lửa CB10/100 chủ yếu bao gồm bốn phần: quá trình mồi, phân phối chất lỏng, cơ chế làm mát và giám sát tốc độ

1 Van kiểm tra đảm bảo lưu lượng một chiều của chất lỏng, ngăn chặn dòng chảy ngược Quá trình này là nhanh chóng và hiệu quả, tiết kiệm thời gian quý giá cho các nỗ lực chữa cháy tiếp theo

2 Phân phối chất lỏng: Chất lỏng được đưa vào bơm được tăng tốc và đẩy qua cấu trúc ly tâm cánh quạt hai giai đoạn dưới tác động của bánh công tác, tạo thành dòng nước áp suất cao Quá trình này cho phép máy bơm lửa nhanh chóng cung cấp nước hoặc tạo bọt các tác nhân dập tắt đến nguồn lửa, dập tắt hiệu quả đám cháy

3 Cơ chế làm mát: Trong quá trình hoạt động của máy bơm lửa, hộp số và vòng bi tạo ra một lượng nhiệt đáng kể Để duy trì nhiệt độ ổn định và ngăn ngừa quá nóng, lưu thông nước làm mát trong các ống làm mát liên tục chảy để làm tan nhiệt được tạo ra, đảm bảo hoạt động bình thường của máy bơm

4 Giám sát tốc độ: Thiết bị đo tốc độ theo dõi tốc độ quay của máy bơm trong thời gian thực và truyền dữ liệu đến hệ thống điều khiển Các nhà khai thác có thể điều chỉnh trạng thái làm việc của máy bơm dựa trên các dữ liệu này để đảm bảo nó luôn hoạt động trong phạm vi làm việc hiệu quả

Iv Đề xuất bảo trì cho máy bơm lửa CB10/100

Để đảm bảo tuổi thọ hiệu quả cao và dịch vụ dài của máy bơm chữa cháy CB10/100, đây là một số gợi ý bảo trì chính:

1 Kiểm tra và bảo trì thường xuyên:

o Thường xuyên kiểm tra mồi bốn piston và thay thế các bộ phận bị mòn kịp thời để đảm bảo mồi mịn

o Kiểm tra dấu của van kiểm tra để đảm bảo nó tốt, ngăn chặn dòng chảy chất lỏng có thể ảnh hưởng đến hoạt động bình thường của máy bơm

o Kiểm tra bánh công tác và van để mòn và ăn mòn, và thay thế chúng nếu cần thiết để duy trì hiệu quả cao của máy bơm

2 Bảo trì hệ thống làm mát:

o Thường xuyên làm sạch quy mô và tạp chất từ các ống làm mát để đảm bảo lưu lượng nước làm mát mịn và ngăn ngừa các vấn đề quá nhiệt gây ra bởi tắc nghẽn

o Kiểm tra sự bôi trơn của hộp số và vòng bi, và thường xuyên thêm hoặc thay thế dầu bôi trơn để giảm hao mòn và kéo dài tuổi thọ dịch vụ

3 Kiểm tra con dấu:

o Thường xuyên kiểm tra các con dấu trên khắp cơ thể bơm để đảm bảo không có rò rỉ, ngăn ngừa sự suy giảm hiệu suất hoặc các mối nguy hiểm an toàn do rò rỉ

o Thường xuyên thay thế các con dấu của trục đầu vào để ngăn bụi và tạp chất xâm nhập vào bơm và ảnh hưởng đến hoạt động bình thường của nó

4 Giám sát tốc độ và kiểm tra động cơ:

o Thường xuyên kiểm tra trạng thái làm việc của thiết bị đo tốc độ để đảm bảo nó theo dõi chính xác tốc độ bơm và cung cấp hỗ trợ dữ liệu chính xác cho các nhà khai thác

o Kiểm tra trạng thái vận hành của động cơ ổ đĩa để đảm bảo sự tương tác bình thường giữa động cơ và bơm, ngăn máy bơm bị trục trặc do lỗi của động cơ

5 Điều trị và lưu trữ chống ăn mòn:

o Chọn các vật liệu cánh quạt thích hợp dựa trên môi trường hoạt động và áp dụng lớp phủ chống ăn mòn nếu cần thiết để cải thiện khả năng chống ăn mòn của máy bơm

o Khi lưu trữ máy bơm lửa, chọn một nơi khô ráo, thông thoáng để ngăn chặn sự suy giảm hiệu suất do độ ẩm hoặc ăn mòn

Bằng cách làm theo các đề xuất bảo trì này, máy bơm chữa cháy CB10/100 có thể duy trì hiệu quả cao và hiệu suất đáng tin cậy trong các trường hợp khẩn cấp, cung cấp hỗ trợ mạnh mẽ cho các nỗ lực chữa cháy.